Understanding the Top OSHA Crane Violations

Contractors use truck-mounted boom cranes and articulating cranes to efficiently move materials to and from job sites. With proper training and when used correctly, cranes are an incredibly effective and valuable tool for contractors and suppliers alike.

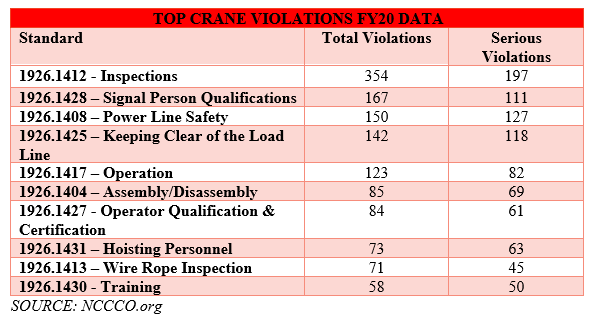

There are, however, crane operators whose actions put others, themselves, and property in harm’s way. The following is a list presented by OSHA for the top violations in 2020 and pertains to all industries using a crane and is therefore not specific to roofing or roofing supply. By being cognizant of the failures of others, owners and/or operators can ensure that they are safely operating their cranes, and if not, immediately provide corrective actions.

1926.1412 Inspections - At least every 12 months the equipment must be inspected by a qualified person. When a customer brings their crane to Runnion Equipment, our factory-trained technicians will do an in-depth, visual and operational inspection of their crane and put the machine through its normal operating cycles with safety covers removed to accurately inspect concealed areas. Also, a competent person must begin a visual inspection prior to each shift the equipment will be used, which must be completed before or during that shift.

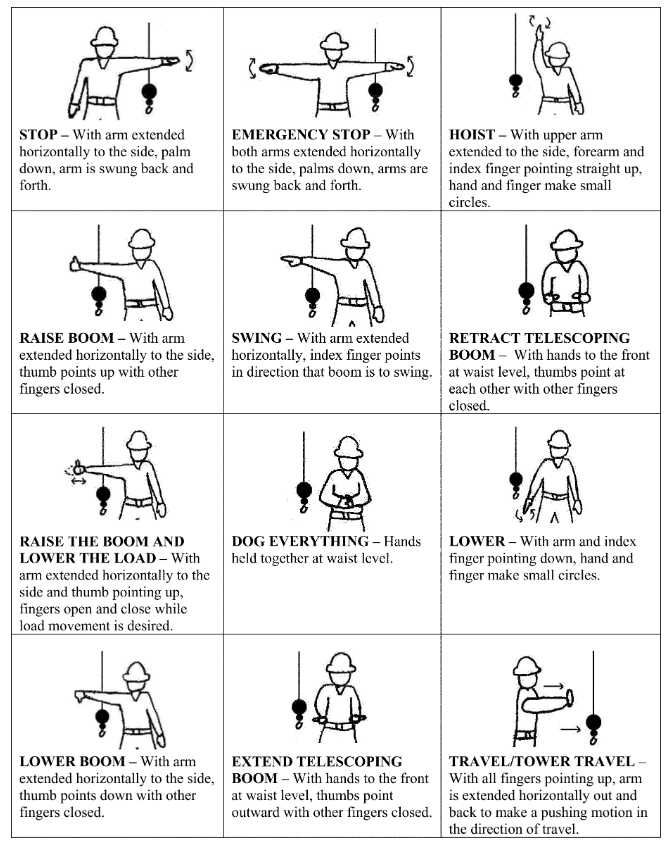

1926.1428 Signal Person Qualifications – OSHA requires that the employer of the signal person (e.g. the person on the roof directing the crane operator) be qualified. To be qualified, the signal person must demonstrate through a test (oral or written) and a practical test, that they "know and understand the type of signals used, be competent in the application of the type of signals used, have a basic understanding of equipment operation and limitations, and know and understand the relevant requirements."

OSHA 29 CFR 1926, Subpart CC, Appendix A

1926.1408 Power Line Safety – When setting up a crane, an operator has to look up and identify any overhead obstacles that might have an effect on the lifts, particularly the operator needs to be keenly aware of power lines. The closest any part of the crane should get to any powerline under 350 kV is 20 feet. On a National Crane with a RCL computer, an operator can program the crane to alert them as they approach a pre-determined point such as power lines. If the crane will have to operate closer than 20 feet, OSHA 1926.1407 outlines the steps to take.

1926.1427 Operator Qualification & Certification - By now everybody is keenly aware of the OSHA requirement to have their operators be certified. Runnion Equipment hosts classes throughout the year for boom cranes (both stand up and swing seat) and articulating (including drywall booms).

1926.1413 – Wire Rope Inspection - The crane operator needs to ensure their lifting equipment such as the wire rope, slings, rigging, and hook is safe to use. A competent person needs to check the wire rope on a daily and monthly basis and ensure that it is free of kinks, bird caging, or excessive broken wires (documentation of the monthly inspection is required). The hooks must be equipped with a working latch and the ID tags on the hook and straps must be legible. If lifting straps are damaged in any way, they must be taken out of service.

When workers are present on a site where cranes are being used, employers are responsible for ensuring that these workers are not exposed to any crane-related hazards even if an organization doesn’t use cranes themselves. Employers need to know the standards and train their employees accordingly if they might be affected by another on-site contractor.

All workers on a job site must be able to recognize and avoid hazards and training is absolutely the first step on the way to achieving this goal.

Safe operations of cranes and other equipment on the jobsite depend on the training and dedication of the people involved. Employers need to encourage workers to engage in safe behaviors. Simply knowing the rules does not mean that they will be followed. A firm safety culture must be in place so that employees focus on performing their jobs in a safety conscious manner with a concern for their fellow workers as well as property and bystanders in the area.

Visit https://www.osha.gov/cranes-derricks/ for an in-depth look on these issues.